Spreading Machine For Garment Production Process

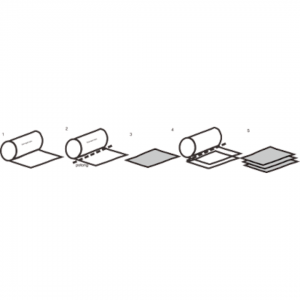

A spreading machine is one of the tools used in the garment production process. The spreading machine is used so that the final product of clothing production has good quality and meets standards. The purpose of deploying the fabric is that the resulting material/fabric becomes more consistent, precise and gets a pile of fabric that is ready to be cut according to the pattern that has been made.

In the method of spreading cloth, there are two ways of deploying it, namely by One Way and Two Way. We have discussed these two terms in the previous article.

- One Way

As the name implies, one way is a one-way cut. One way is a method of rolling out the cloth in which the cloth is rolled out of a cloth roll and cut at the end close to the cloth roll when the length of the cloth is desired.

2. Two Way

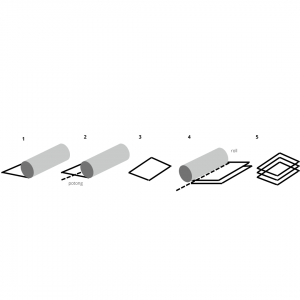

While two-way is the direction of cutting in two directions. Two way is to roll out the fabric by means of a roll of fabric running from a different direction than the length of the fabric.

To suit your various needs, Pukka Indonusa provides a wide selection of spreading machines including the K5 Spreading Machine, HR Spreading Machine, Maestro-Spreading Machine, and iRun Spreading Machine. Each of these four machines has its own advantages.

With a spreading machine, it will be easier for you to get the final result of maximum clothing production. Get in touch with us and find other solutions for your business only at Pukka Indonusa!

Would you like to share your thoughts?